HELP YOU ACHIEVE CONSISTENCY

Fiber Laser/SSL

MAIN FEATURES

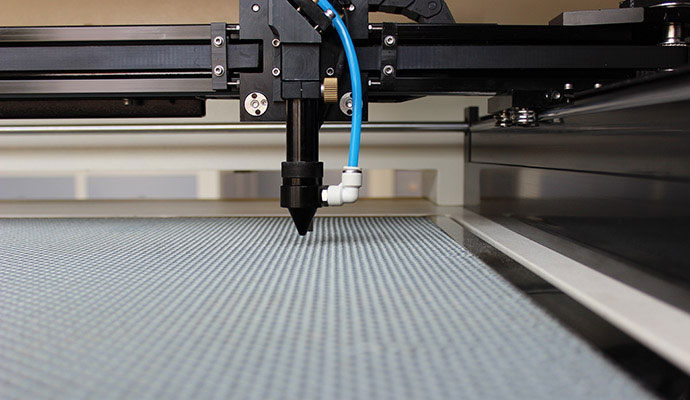

CO2 Laser

Highlights

No moving parts or mirrors

No moving parts or mirrors

The fact that it has no moving parts means that your fiber laser setup is ready to get working from the get-go. And, should it be knocked, none of the parts will come out of alignment; resulting in costly production down time.

Lower maintenance costs

The second advantage to the fact that fiber lasers are extremely insensitive, as described above, is that it means maintenance costs are dramatically lower, as are operational costs and with ‘fit and forget’ technology there is no maintenance cycle or servicing to worry about.

Electrical efficiency

Another cost saving benefit is that fiber lasers are much more efficient when it comes to electricity, meaning lower running costs and a more environmentally friendly machine. For example, a 3 kW fiber laser uses only a third of the power of that of a 4 kW CO2 laser .

Good with thin materials

Although fiber lasers are good at working with materials of all thicknesses, they are particularly great at working with thin materials, including metals. Using the same comparison of lasers as above, the fiber laser is three times faster at cutting in a straight line on something like stainless steel with a 1mm thickness, and two times faster if the same material is 2mm in thickness.

Reflective metals

Something that we’ve demonstrated in one of our videos is that fiber lasers can cut reflective materials without having to worry about back reflections that could damage the machine.

Advantages of CO2 lasers

Works well with thicker materials

Fiber lasers can work with thicker materials no problem, but generally a CO2 laser will leave a surface finish that is smoother.

Faster in a straight line

A CO2 laser is faster at cutting in a straight line, as well as having a quicker piercing time when the cut is first started.

The main disadvantages of CO2 lasers are where the advantages of fiber lasers lie. Firstly, CO2 lasers are sensitive machines that require alignment, so should this get knocked out of place, usually an expert is required to fix it, resulting in long periods of down time when the laser is not being productive.

This also means they need more regular servicing, and the costs of this maintenance are higher. Alongside this, more power is needed, resulting in higher electrical costs. CO2 lasers are also slower at cutting thin materials, and aren’t able to work with reflective metals to a good degree.