Laser cladding technology is a surface strengthening method that rapidly heats and melts the alloy powder or ceramic powder and the substrate surface under the action of laser beam, and cools after the beam is removed to form a surface coating with very low dilution rate and metallurgical combination with the substrate material, so as to significantly improve the wear resistance, corrosion resistance, heat resistance, oxidation resistance and electrical characteristics of the substrate surface.

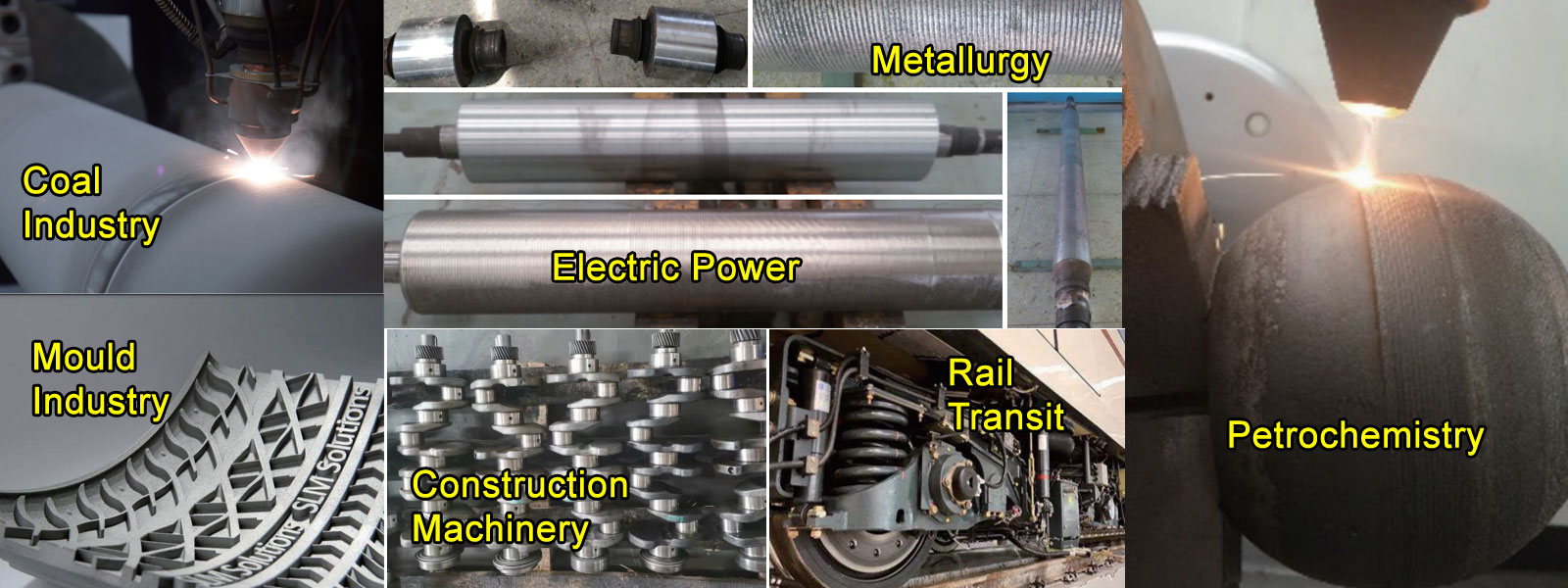

As a green processing technology, laser cladding is a new technology with high economic benefits. It can prepare high-performance alloy surfaces on cheap metal substrates without affecting the properties of the substrate, reduce costs and save precious and rare metal materials. Its application covers the whole machinery manufacturing industry, including mining machinery, petrochemical industry, electric power, railway, automobile, shipbuilding and metallurgy, aviation, power, mold and other industries.

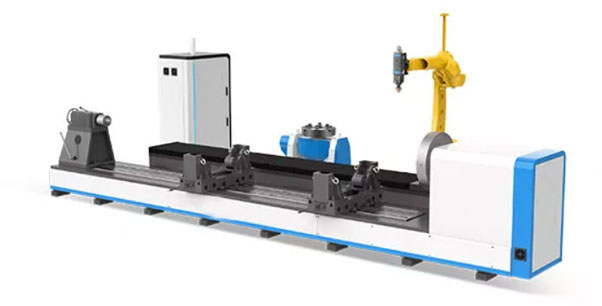

Robot Laser Cladding Machine

Metal Additive Machine

Metal Laser Cladding Machine

Mobile Robot Laser Cladding System

The optical path and circuit module do not interfere with each other and work stably; The photoelectric module can be directly replaced, upgraded and maintained at the client.

Level 3 Return protection and PD rapid monitoring are added to avoid damage to the laser during the processing of high reflection materials and ensure the safety of the laser.

The output power of single-mode group is up to 3KW, and the equipment integrated with 10000 watt laser is smaller.

Electro optic conversion efficiency ≥ 35%, more energy saving.